ARC 400GT

ARC MMA Welder / Inverter Welding Machine

- Stable welding performance: market proven performance, improved technology, providing high arc stability and welding reliability;

- Long-time welding: max. output current 380A, high duty cycle, continuous welding of Ø4.0/5.0mm E6013, E7018, E7016, E6011 acid and basic electrodes, a good choice for industrial applications;

- Extension cable: the welder can automatically adjust the output voltage to compensate the loss, able to work with extension cable of up to 100 meters;

- Professional functions: with meter display, built-in anti-stick, adjustable arc force and hot arc start, satisfying the application needs of different welding positions;

- Dust free cooling system: efficiently cutting down on the dust amount and prolonging the service life, able to adapt to harsh environments;

- Anti-shock protection: VRD anti-shock design protects operator against electric shocks, reducing no-load voltage and ensuring work safety;

- Classic design: classic appearance design, multiple functions, and with corner protectors;

| Model | |

| Input voltage | 3PH 380V (±15%) |

| Frequency | 50/60Hz |

| Rated power | 18.2kVA |

| Duty cycle (40℃) | 40% |

| No-load voltage (with VRD) | 15V |

| No-load voltage (without VRD) | 62V |

| Current adjusting range | 40-380A |

| Hot start adjusting range | 0-10 |

| Arc force adjusting range | 0-10 |

| Efficiency | 85% |

| Power factor | 0.93 |

| Protection grade | IP21 |

| Insulation class | Class H |

| Anti-shock protection | Class I |

| Electromagnetic Compatibility (EMC) | A |

| Static characteristic | Drooping characteristic |

| Cooling method | Forced air cooling |

| Net weight (kg) | 18.5kg |

| Dimensions (L×W×H) | 508×244×423mm |

Rebar welding

Rebar welding Excavator part welding

Excavator part welding Pipeline welding

Pipeline welding I-beam welding

I-beam welding Steel structure

Steel structure Steel angle welding

Steel angle welding

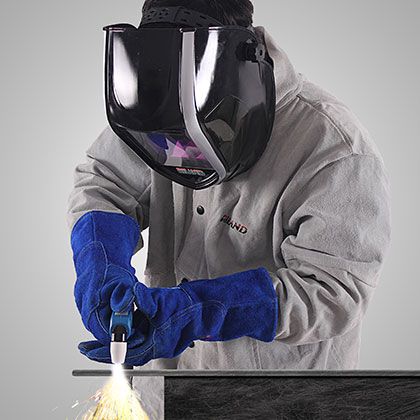

3mm-thick carbon steel vertical fillet welding (2.5 welding rod)

3mm-thick carbon steel vertical fillet welding (2.5 welding rod) 5mm-thick carbon steel vertical fillet welding (3.2 welding rod)

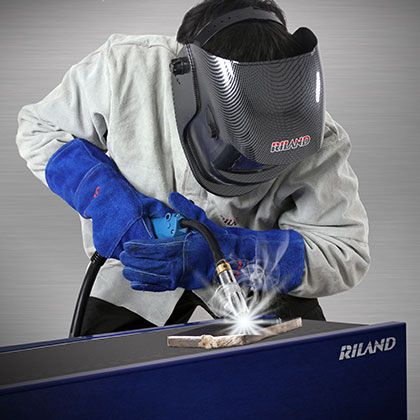

5mm-thick carbon steel vertical fillet welding (3.2 welding rod) Carbon steel fillet welding (4.0 welding rod)

Carbon steel fillet welding (4.0 welding rod) Carbon steel fillet welding (5.0 welding rod)

Carbon steel fillet welding (5.0 welding rod)

15mm-thick steel plate welding (5.0 welding rod)

15mm-thick steel plate welding (5.0 welding rod)  Pipeline welding (4.0 welding rod)

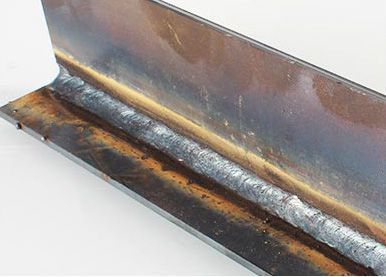

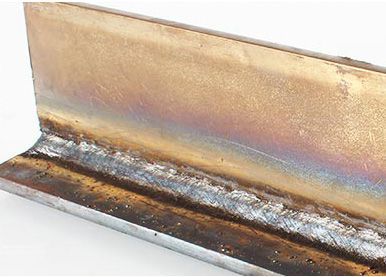

Pipeline welding (4.0 welding rod) 3mm-thick steel angle welding (3.2 welding rod)

3mm-thick steel angle welding (3.2 welding rod)

Get in Touch

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.

Read MoreRelated Products

-

- ARC 500GT

ARC MMA Welder

IGBT inverter technology, high switching frequency and rapid response;

-

- ARC 251C

ARC MMA Welder

Improved welding performance and arc stability, arc starting with comparatively low voltages;

-

- ARC 200CT

ARC MMA Welder

RILAND is specialist manufacturer of portable welding machines, including MMA welders, TIG welders, MIG welders and robotic welding systems.

-

- ARC 200GT & ARC 250GT

ARC MMA Welder

Equipped with RILAND’s self-developed RICHI chip and use the 70KHz latest high grade IGBT technology;

Wide range input voltage: 220V±15%;