Rail Guided Welding Carriage

- Control system is integrated with the fillet welding carriage;

- Digital LED display for clear showing and precise setting of various parameters;

- Multiple welding modes are selectable, realizing different welding paths;

- Available in 2T/4T function, adjustment of arc starting and arc suppression time via welding carriage;

- Configured with HIT-33 oscillator to achieve left/center/right dwells, the dwell time and oscillator speed are adjustable;

- Configured with HIT-30 oscillator to achieve adjustment of oscillation amplitude and speed accordantly;

- Horizontal welding torch holder can be equipped, conducting inclined oscillation motion when welding in the horizontal position as well as fillet welding, so that molten weld pool does not tend to flow down thereby obtaining a good weld seam formation;

- Capable of implementing all-position welding on workpieces having thin and medium-thick metal plates, with high welding efficiency;

- Track sections can be joined together to realize long seam welding;

Our RL-1CM welding carriage with electronic oscillator is mainly consisted of carriage body, cross slide and control box. Four wheels under the carriage body enable the welding carriage to travel along the track, the control box is designed with forward/stop/reverse switch and handle used for travel wheel control.

| Model | | |

| Input voltage (V) | AC220V/DC24V | AC220V/DC24V |

| Rated power (W) | 22 | 25 |

| Travel speed (mm/min) | 0-820 | 0-700 |

| Magnetic force (kg) | 100 | 50 |

| Torch adjustment range (mm) | Up/down: 50mm Left/right: 50mm | Up/down: 50mm Left/right: 50mm |

| Torch angle | 0-360 | 0-360 |

| Absorption method | Magnetic absorption (track switch) | Magnetic absorption (track switch) |

| Guiding | Track | Track |

| Applicable oscillator model | 33 oscillator &30 oscillator | 33 oscillator &30 oscillator |

| Weight (kg) | 10.5 | 8.5 |

| Overall dimensions (L×W×H) (mm) | 220×150×245 | 280×390×245 |

Get in Touch

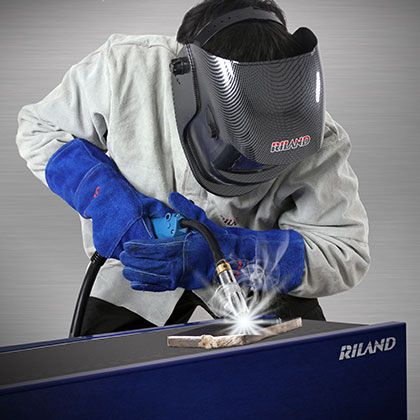

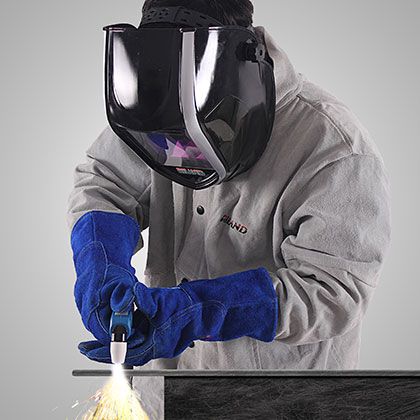

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.

Read MoreRelated Products

-

Automated Gouging System

Professional gouging torch combined with travel carriage is featured by low noise level, less spatter, reduced dust and low energy consumption, ideally alternative to carbon arc gouging system;

-

Welding Oscillator

Welding oscillator controls the welding torch with oscillating movement by simulating conditions of various welding modes;

-

Horizontal Fillet Welding Carriage

24V safe power supply, lithium battery can be configured for continuous operation without requiring external power source;

-

Trackless Fillet Welding Carriage

Suitable for horizontal fillet welding of steel angles, H-beams and T-beams;