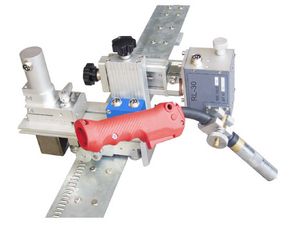

Welding Oscillator

- Welding oscillator controls the welding torch with oscillating movement by simulating conditions of various welding modes;

- Oscillation speed and amplitude are adjustable;

- Torch holder can be adjusted in an angle range of 0-360°;

- Oscillation amplitude of 0-8° in single direction;

- Deliberate mechanical design, the motor runs at constant speed to enable the welding torch to operate with precise motion, efficiently avoiding the issue that the torch oscillation speed slows down at the both ends of the oscillation path when varying the rotation direction of motor, thus prolonging the service life of welding oscillator;

| Model | | | | |

| Oscillation speed (cycles/min) | 74 | 74 | 74 | |

| Oscillation amplitude | Radius 120mm | 17 | 23 | 21 |

| Radius 180mm | 25 | 34 | 31 | |

| Radius 200mm | 27 | 38 | 34 | |

| Weight (kg) | 1 | 1.5 | 1.5 | |

| Left dwell time (S) | - | - | 0-2.1 | |

| Center dwell time (S) | - | - | 0-2.1 | |

| Right dwell time (S) | - | - | 0-2.1 | |

| Delay time (S) | - | - | 0-5.1 | |

| Max. load (kg) | 4 | 4 | 4 | |

| Power supply (V) | DC 24V | DC 24V | DC 24V | |

| Output power (W) | 12 | 12 | 15 | |

| Dimensions (Mm) | 105×135×125 | 130×110×140 | 150×110×140 | |

| Welding positions | Horizontal fillet welding, vertical fillet welding, horizontal groove welding, vertical groove welding, overhead welding, flat welding, etc. | |||

Get in Touch

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.

Read MoreRelated Products

-

Trackless Fillet Welding Carriage

Suitable for horizontal fillet welding of steel angles, H-beams and T-beams;

-

Vertical Fillet Welding Carriage

Automatic fillet welding in vertical position, guide arm for proper carriage positioning without the need for track;

-

All-position Fillet Welding Carriage

Automatic fillet welding in all welding positions, guide arm for proper carriage positioning without the need for track;

-

Rail Guided Welding Carriage

Digital LED display for clear showing and precise setting of various parameters;