RILAND is a national high-tech company focused on the design, manufacture and supply of inverter welding and cutting equipment, automated robotic welding systems, welding accessories and welding safety equipment, and providing the best service to global customers. RILAND started its business in 2003 with the registered capital of 455.24 million RMB, and was listed on the Growth Enterprise Market (GEM) of Shenzhen Stock Exchange in December 2010, becoming an A-share listed company in the domestic inverter welding equipment industry (stock code: 300154). Our continuous growth and improvement over the years is based on our team of nearly 1,000 enthusiastic people, including approximately 200 technicians who have long been engaged in the welding industry.

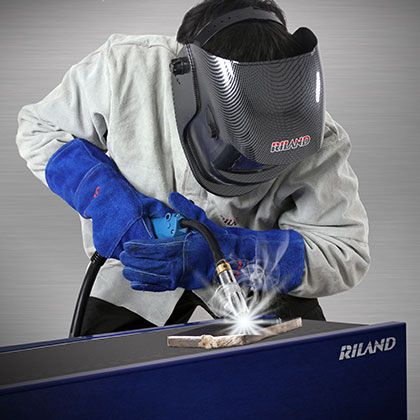

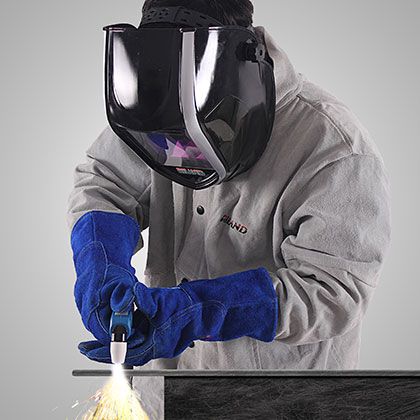

Today, RILAND has several brands in its portfolio, such as Riland, Rilon and Ownace, with more than 100 models. Our huge variety of products includes inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. Due to the premium quality and high cost effectiveness of our arc welding and cutting equipment, we have been serving numerous customers across a multitude of industries such as chemical, oil pipeline, automobile, shipbuilding, steel structure, boiler, power construction, nuclear power, aerospace, military, bridge construction, and more industrial installation applications.

At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. As early as 1987, the founder of RILAND, Mr. Qiu Guang developed the first inverter MOSFET manual arc welding machine in the domestic market. In subsequent years, we have developed inverter TIG welding machine, CO2 MIG welding machine and air inverter plasma cutting machine which were pioneered in the domestic market. Besides, the first 100kHz frequency inverter technology has promoted the intensification and lightweight of welding equipment.

Since the day of its foundation in 2003, RILAND has aimed at pioneering technological innovation and focused on maintaining a leading position in the competitive market. With state-of-the-art R&D laboratory and advanced equipment, our team of seasoned professionals is large enough to identify the best solution for every customer. In October 2009, RILAND established cooperative partnership with the National Key Laboratory of Advanced Welding Production Technology to set up the National Digital Welding Laboratory. Our R&D center has been recognized as Innovation Industrialization Demonstration Base of Guangdong Province, Shenzhen Engineering Center and Bao'an District Research & Development Base. RILAND has participated in the formulation of 21 national standards of welding and cutting equipment. Until 2021, RILAND has been granted 268 patents including 41 invention patents, 117 utility model patents, 45 design patents and 7 computer software copyright registration certificates. Currently, we have 7 patents are pending.

RILAND has long insisted on the philosophy of "Integrity Management, Continuous Innovation". We strive to earn the ongoing trust of our customers with leading technology development, strict quality control and excellent after-sales service. To date, our sales and service network covers more than 60 countries and regions, with nearly 100 overseas distributors and over 2000 domestic distributors.

With many years of experience in the welding industry, RILAND has cultivated its core competence that lies in independent innovation, and enterprise advantages regarding aspects of brand channel, talent management and quality control. RILAND currently has 10 holding subsidiaries, and the company continues to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.