Speed Control Technology for Wire Feeder Motor

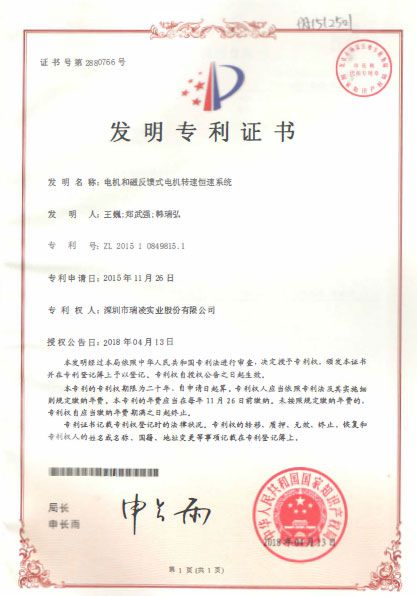

It is a motor with constant speed system through magnetic feedback method. The motor is composed of a motor housing that has a cooling cavity at one side, a rotating shaft with one end embedded into the cooling cavity, a cooling fan linked to the motor shaft, a magnet (or more) attached to the cooling fan for following the fan rotating motion, linings of cooling cavity and a Hall sensor. The Hall sensor measures the strength of a magnetic field, therefore producing an output signal corresponding to the speed of motor rotation.

Technological advantage

This technology aims at lowering motor cost, improving anti-vibration ability, as well as precise control of motor speed. By using the technology, our wire feeder operates with closed-loop control and unique software algorithm to ensure constant high torque at low-speed running, thus providing constant speed through the entire wire feeding process. This control technology plays a vital role in achieving one-key control of MIG welding machine. At the same time, our independently developed chip along with built-in welding expert database helps simplify welding parameter combinations while guaranteeing welding reliability and stability.

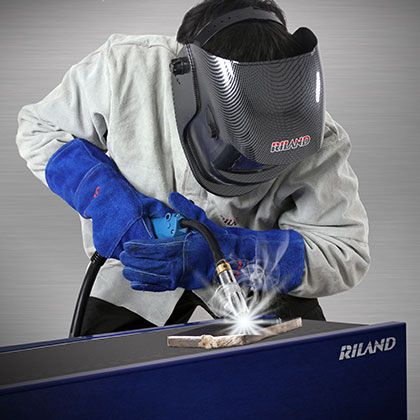

Technology used in welding machines

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.