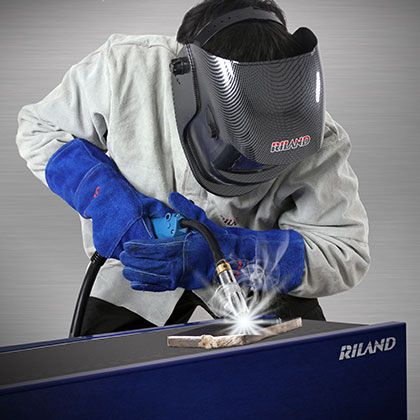

Welding machines: NB 500I, NB 350I, NB 630I

- IGBT inverter technology, providing high reliability and better arc stability;

- Multi-process welders, designed with MIG welding, MMA welding and carbon arc gouging functions;

- 60% duty cycle at 40℃, providing excellent welding performance, ideal option for users in heavy industry;

- Effective CTWD (Contact to Work Distance) for adaptive loop is less than 30mm, suitable for welding in all positions;

- Waveform control of droplet transfer ensures high arc stability, less spatter and good welding seam formation;

- Removing tip ball after welding, ensuring high success rate of arc starting;

- Particularly suitable for welding applications in the steel structure and shipbuilding industry;

- Hardware Manufacturing

- Automobile Industry

- Shipbuilding

- Construction & Infrastructure

- Chemical & Oil Pipeline

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.