- Productivity

- Based on our large-scale production management system with occupational division of labor, we have the ability to produce a welding machine every 38 seconds on average. Our annual output can reach 700,000 units.

- Quality assurance

- We strictly control the quality of our products through all aspects of operator qualification, incoming material inspection, production process monitoring through to final examination, thus guaranteeing the quality of every product in conformity with rigid standards of excellence.

- Cost effectiveness

- RILAND uses discrete devices instead of using power modules which are more expensive to repair if any component is damaged, and a number of standard components are used in the production process. In addition, our technological platform is established for large-scale mass production, significantly improving working efficiency while lowering manufacturing cost. Our inverter welding and cutting equipment are cost-effective and efficient means alternative to conventional welding and cutting equipment.

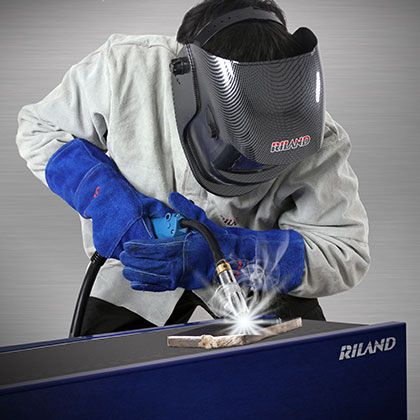

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.