-

R&D

RILAND is always striving for constant growth and improvement via independent innovation that is regarded as the core task, and focusing on maintaining a leading position in technologies within the welding industry.

-

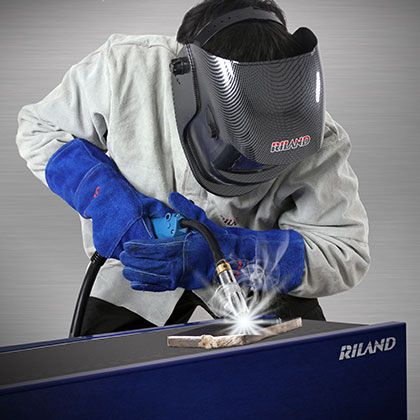

Manufacturing

Based on our large-scale production management system with occupational division of labor, we have the ability to produce a welding machine every 38 seconds on average. Our annual output can reach 700,000 units.

-

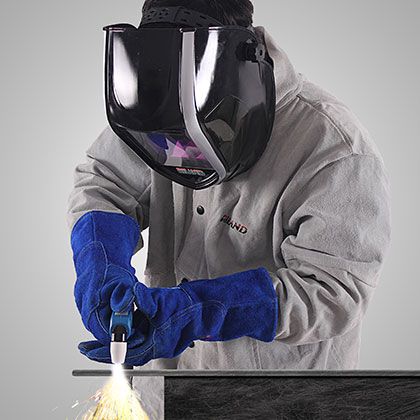

Core Technology

It is a motor with constant speed system through magnetic feedback method. The motor is composed of a motor housing that has a cooling cavity at one side, a rotating shaft with one end embedded into the cooling cavity, a cooling fan linked to the motor shaft, a magnet (or more) attached to the cooling fan for following the fan rotating motion, linings of cooling cavity and a Hall sensor. The Hall sensor measures the strength of a magnetic field, therefore producing an output signal corresponding to the speed of motor rotation.

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.