- RILAND is always striving for constant growth and improvement via independent innovation that is regarded as the core task, and focusing on maintaining a leading position in technologies within the welding industry.

- The founder of RILAND, Mr. Qiu Guang developed the first inverter MOSFET manual arc welding machine in the domestic market as far back as 1987.

- In 1990, we developed the world's first "100kHz Frequency Inverter Technology" and brought it to the global market, significantly lowering the manufacturing cost of inverter welding and cutting equipment. It was recognized as a revolutionary innovation in the welding field at the time.

- RILAND was the domestic forerunner in developing and launching inverter TIG welder, inverter CO2 MIG welder, inverter air plasma cutter, inverter multi-process welder and other inverter welding and cutting equipment, and has obtained a number of national patents.

- We were the first domestic company that has successfully developed "symmetric bridge structure inverter technology" and "over-current protection technology".

- In 2011, RILAND has achieved a breakthrough that significantly advances the high-efficiency and automated welding technology. Our digital pulse welding equipment and robotic welding systems have reached the industry-leading level, filling the gap in the domestic market.

- Until 2021, RILAND has been granted 268 patents including 41 invention patents, 117 utility model patents, 45 design patents and 7 computer software copyright registration certificates. Currently, we have 7 patents are pending.

Complete R&D system, at the forefront of technology

At RILAND we have made a firm commitment to continually invest in innovative solutions to ensure we have proprietary intellectual property rights for the core technology, positioning ourselves in the vanguard of technology development within the welding field. In 2011, we have spent 36.86 million RMB on investment in research and development, accounting for 4.85 percent of the total income. In 2015, our R&D investment reached 28.31 million RMB, accounting for 5.12 percent of the total income. Out team of nearly 200 technicians and engineers is dedicated to continually pushing the limits of innovation.

University-industry research collaboration

Apart from paying attention to technological innovation, RILAND has partnered with world's renowned brands, domestic accredited laboratories and universities.

Partners

In 2009, RILAND and the National Key Laboratory of Advanced Welding Production Technology has jointly set up the "National Digital Welding Laboratory". RILAND plans to establish eight high-grade laboratories, aiming at ensuring us to stand out from our competitors and earning the ongoing trust of our customers, taking our inverter welding machines ahead of the competition in the domestic market.

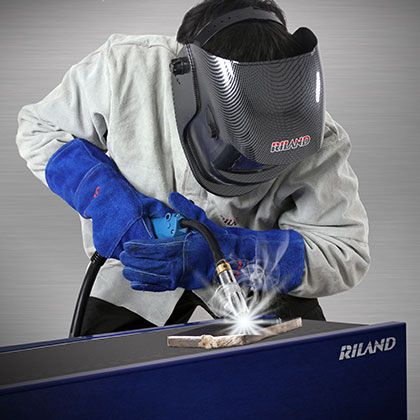

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.