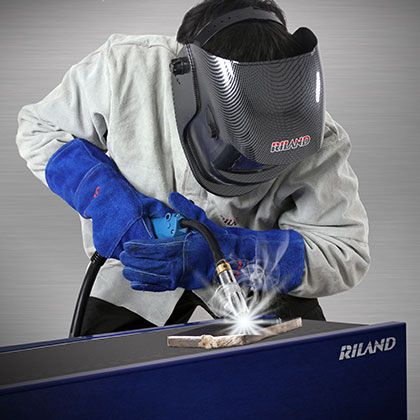

Stainless Steel / Aluminum Alloy Welding Solution

Pulse welding: versatile for welding a variety of materials, good welding seam formation

Welding of plate heat exchanger for automotive industry

Industrial Sectors of RWAS Robotic Arc Welding PackageDue to its premium quality and high cost effectiveness, our RWAS robotic arc welding packages have extensive applications across a multitude of industry sectors, including oil pipeline, chemical, automobile, shipbuilding, boiler, power construction, nuclear power, aerospace, military, bridge construction, etc.

Electric power industry

Electric power industry Chemical industry

Chemical industry Shipbuilding industry

Shipbuilding industry Construction industry

Construction industry Electric power industry

Electric power industry Storage tank industry

Storage tank industry

| Model | | | | | |

| Payload | 6kg | 12kg | 20kg | 10kg | |

| Reach | 1450mm | 1510mm | 1780mm | 2000mm | |

| Repeatability | ±0.08mm | ±0.05mm | ±0.06mm | ±0.07mm | |

| Mass | 155kg | 170kg | 245kg | 248kg | |

| Working range | Axis 1 | ±170° | ±170° | ±180° | ±180° |

| Axis 2 | -60°/+160° | -60°/+160° | -95°/+160° | -95°/+160° | |

| Axis 3 | -155°/+85° | -165°/+88° | -170°/+80° | -170°/+80° | |

| Axis 4 | ±170° | ±180° | ±180° | ±180° | |

| Axis 5 | ±180° | ±140° | ±140° | ±140° | |

| Axis 6 | ±360° | ±360° | ±360° | ±360° | |

| Max. speed | Axis 1 | 180°/S | 190°/S | 185°/S | 185°/S |

| Axis 2 | 180°/S | 180°/S | 185°/S | 185°/S | |

| Axis 3 | 180°/S | 190°/S | 190°/S | 190°/S | |

| Axis 4 | 440°/S | 370°/S | 355°/S | 355°/S | |

| Axis 5 | 400°/S | 375°/S | 360°/S | 360°/S | |

| Axis 6 | 600°/S | 600°/S | 585°/S | 290°/S | |

| IP rating | IP54 | ||||

| Number of axes | 6 axis | ||||

| Installation method | Floor | ||||

Get in Touch

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.

Read MoreRelated Products

-

Medium-thick Carbon Steel Sheet Welding Solution

Deep penetration welding (short arc length): high power output, adequate penetration and good welding quality

-

Thin Carbon Steel Sheet Welding Solution

Spot welding: high weld seam quality, low spatter, fast welding speed