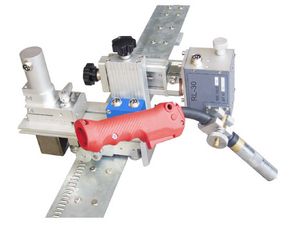

Vertical Fillet Welding Carriage

- Compact size and lightweight, simple to install and easy to carry to the jobsite;

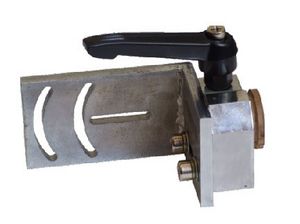

- Automatic fillet welding in vertical position, guide arm for proper carriage positioning without the need for track;

- Configured with RL-30 oscillator, suitable for welding workpieces of different thicknesses with high weld quality;

- Digital LED display for clear showing and precise setting of travel speed;

- Internal drive system has dustproof and anti-magnetic design, prolonging service life;

- Adopting gear transmission system, avoiding the issues of loosening that often occur in chain transmission system;

- Anti-fall device is used as standard configuration, it protects both operator and carriage against vibrations caused by impacting of workpiece;

- RL-10 fillet welder can not only perform fillet welding in vertical position, but also realize horizontal fillet welding by carriage absorption on side wall;

- RL-10MK fillet welder is an anti-collision welding carriage that has two anti-collision switches, which make the carriage to automatically stop travelling and start welding when it touches the targeted workpeice;

| Model | | | |

| Input voltage (V) | AC220V/DC24V | AC220V/DC24V | AC220V/DC24V |

| Rated power | 25w | 25w | 25w |

| Travel speed (mm/min) | 0-700 | 0-700 | 0-700 |

| Magnetic force (kg) | 30 | 30 | 30 |

| Torch adjustment range (mm) | 50;50 | 50;50 | 50;50 |

| Torch angle | 360° | 360° | 360° |

| Absorption method | Permanent magnetic absorption | Permanent magnetic absorption | Permanent magnetic absorption |

| Guiding | Guide arm | Guide arm | Guide arm |

| Applicable oscillator model | RI-30 | RI-30 | RI-30 |

| Weight (kg) | 8.6 | 8.5 | 8.5 |

| Overall dimensions (L×W×H) (mm) | 390×280×245 | 210×230×250 | 200×260×240 |

| Applicable material | Low carbon steel |

| Material thickness | 4-16mm |

| Welding position | Fillet welding, butt welding |

| Min. radius of curvature | R≥500mm |

| Max. height of weld joint | 8mm |

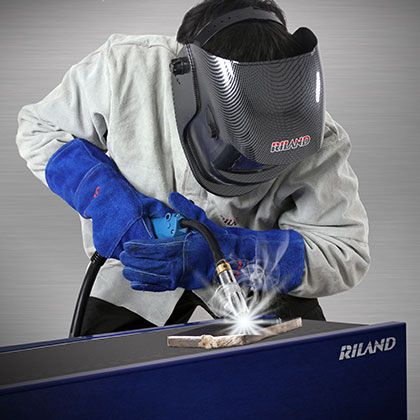

| Applicable power source | CO2 MIG welding power supply |

| Workpiece | T-beam, I-beam, stiffener, etc. |

| Industry | Steel structure, shipbuilding, bridge construction, automobile, power construction, etc. |

Get in Touch

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.

Read MoreRelated Products

-

All-position Fillet Welding Carriage

Automatic fillet welding in all welding positions, guide arm for proper carriage positioning without the need for track;

-

Rail Guided Welding Carriage

Digital LED display for clear showing and precise setting of various parameters;

-

Automated Gouging System

Professional gouging torch combined with travel carriage is featured by low noise level, less spatter, reduced dust and low energy consumption, ideally alternative to carbon arc gouging system;

-

Welding Oscillator

Welding oscillator controls the welding torch with oscillating movement by simulating conditions of various welding modes;