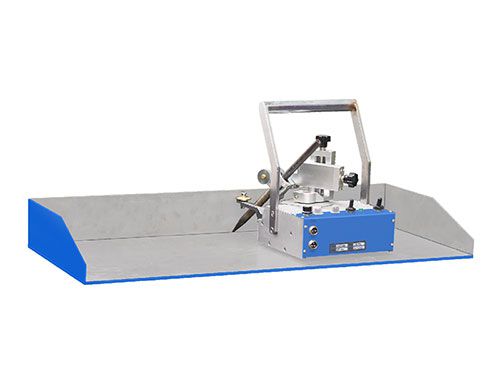

Trackless Fillet Welding Carriage

- Compact size and lightweight, simple to install and easy to carry to the jobsite;

- Several welding modes, welding torch can be moved for welding blind spot area;

- 4-wheel drive, heat resistant silicone wheels, providing high travel stabilization while ensuring superior weld seam appearance;

- Advanced single-chip control, simple operation interface;

- Suitable for horizontal fillet welding of steel angles, H-beams and T-beams;

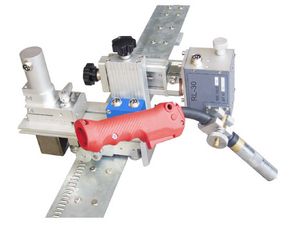

- Automatic arc suppression and carriage travel stopping when the torch sensor detects the metal workpiece, automatic returning of the torch after welding;

- No need for track, guide arm coupled with permanent magnet at the carriage bottom ensures proper guiding and clamping;

- The travel speed of welding carriage is synchronized with the speed of cross slide;

| Model | |

| Input voltage (V) | AC220V/DC24V |

| Rated power | 22 |

| Travel speed (mm/min) | 0-700 |

| Magnetic force (kg) | 25 |

| Torch adjustment range (mm) | 50;50 |

| Torch angle | 90° |

| Absorption method | Permanent magnetic absorption |

| Guiding | Guide arm (no need for track) |

| Applicable oscillator model | ———— |

| Weight (kg) | 7.37 |

| Overall dimensions (L×W×H) (mm) | 217×298×218 |

| Applicable material | Low carbon steel |

| Material thickness | 4-16mm |

| Welding position | Horizontal fillet welding, butt welding |

| Min. radius of curvature | ———— |

| Max. height of weld joint | 8mm |

| Applicable power source | CO2 MIG welding power supply |

| Workpiece | Steel angle, H-beam, T-beam |

| Industry | Steel structure, shipbuilding, bridge construction, automobile, power construction, etc. |

Get in Touch

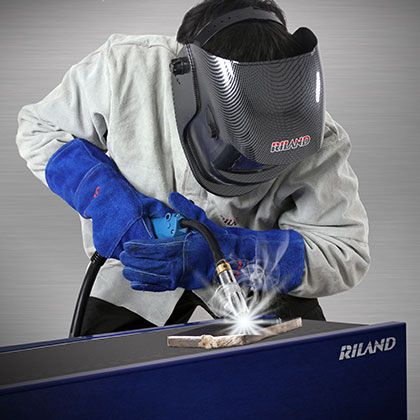

RILAND started its business in 2003 with the goal to design, manufacture and supply inverter welding and cutting equipment, including inverter MMA welders, inverter TIG welders, inverter MIG welders, air inverter plasma cutters, robotic welding systems, automatic welding carriages, digital intelligent welding systems, welding & cutting accessories and welding safety equipment. At RILAND, we do not consider ourselves as only a welding equipment manufacturer, but also position ourselves as an innovative technological force. With many years of development in the welding industry, RILAND currently has 10 holding subsidiaries, and strive to continue to progress steadily towards the next growth target of becoming international first-class comprehensive enterprise of welding equipment.

Read MoreRelated Products

-

Vertical Fillet Welding Carriage

Automatic fillet welding in vertical position, guide arm for proper carriage positioning without the need for track;

-

All-position Fillet Welding Carriage

Automatic fillet welding in all welding positions, guide arm for proper carriage positioning without the need for track;

-

Rail Guided Welding Carriage

Digital LED display for clear showing and precise setting of various parameters;

-

Automated Gouging System

Professional gouging torch combined with travel carriage is featured by low noise level, less spatter, reduced dust and low energy consumption, ideally alternative to carbon arc gouging system;